March was a busy month for Palomar Technologies with exhibiting at both the iMAPS Device Packaging and OFC 2016 technical conferences.

The iMAPS Device Packaging conference was held at the WekoPa Resort and Casino in Fountain Hills, Arizona. More than 525 attendees and exhibitors, from over 19 different countries, participated in this year’s conference. Four topic tracks, 14 technical sessions, and over 80 speakers drew in the crowds. Palomar Technologies has exhibited at this trade show for over a decade.

The four topic tracks were:

- Interposers, 3D IC & Packaging

- Fan-Out, Wafer Level Packaging & Flip Chip

- Engineered Micro Systems/Devices (including MEMS & Sensors)

- System in Package (SIP)

Palomar has solutions for all these packaging processes for both die and wire bonding. Palomar showcased our NEW 3880 ultra flexible, large area, deep access die bonder with it's bi-directional turret making it 2.5 faster in indexing (250 msec/index). Since the turret can move both clockwise and counter clockwise, collet indexing time is up to 15 or more times faster in certain circumstances.

Some of the other advantages of the 3880 Die Bonder are: the color process view camera enhances process generation and build monitoring, the wider force range of 5-1000 grams is derived from a voice coil process rather than solenoid, and planar repeatability is increased by 4 times over our previous model 3800.

Our first level interconnect systems include our 8000i gold ball bonder/ball bumper, and our Model 9000 large area fine wire round and ribbon wire wedge bonder. All three of these units can provide 3D IC, System-in-Package, general hybrid packaging, as well as wafer level and Flip Chip builds.

The Model 8000i can perform ultra-high reliability ball bonding using our Stand-off Stitch processes. It can emulate fine wire wedge bonding in many cases, even for RFSOE builds.

The 9000 Wedge Bonder carries the automatic wire despoiler on its theta mechanism, thus never imparting any twisting or bending of its round wire or ribbon wire bonds.The color process view camera allows for faster process generation, build information from a distance, and can even be used to assist in threading the wire in many applications. Wire bonding speeds of up to 6 wires per second, or up to 10 loops per second in chain bonding mode are possible, material and process dependent.

OFC 2016

The same three units were of great interest at the Optical Fiber Communication Conference and Exhibition (OFC) in Anaheim California the following week. OFC drew more than 13,000 attendees, 580 exhibitors, and 1,160 peer-reviewed technical papers. While OFC has been around for more than 40 years, it was easy to tell this market segment is growing at what seems to be a real and supportable rate.Talk of data rates of up to 500G are mind boggling!

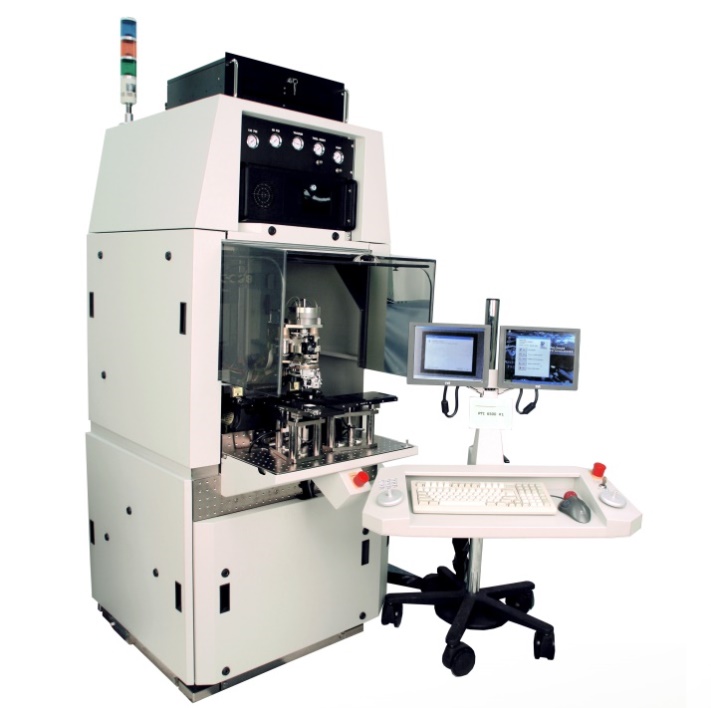

At this technical conference our Model 6500, the ultra-high accuracy die bonder, stood out meeting special needs. Designed with the accuracies needed for p-side down edge emitting laser diode attach to sub-mounts (1.5 micron, 3 sigma), this die bonder delivers solutions for edge emitter and VCSEL laser diodes, back facet monitors, optical elements and more. The 6500 can also provide solutions for Wafer Level Packaging and Active Optical Cables.

Palomar Technologies met with hundreds of customers and potential customers between all of these technical conferences, discussing our capital equipment offerings and our Assembly Services solutions. We will be exhibiting at the iMAPS RAMP technical conference in San Diego this week and the IMS (MTTS) technical conference in San Francisco in May. If you are attending either, please stop by to discuss your current or future packaging challenges. We would be pleased to have in-depth technical discussions about your packaging needs.

Download the following resources for more information:

| Improved Wire Bond Reliability eBook | Micron-Level WSP eBook |

Automating MEMS Assembly Paper |

|

|

|

-------------

Bradley Benton

Regional Account Manager, Western Americas

Palomar Technologies, Inc.