Physical Plasma

Physical Plasma Cleaning is a technology that uses Argon ions to interact physically with matter.

In an SCI Automation (SCI) plasma cleaner, physical plasma @ 13.56 MHz is characterized typically by:

1) The use of Argon gas. Argon is the industry’s choice because of its availability, cost, inert chemical characteristics and molar weight.

2) A low vacuum operating pressure, which defines a lower concentration of ions and a larger mean free path.

3) High ion energy.

4) Low ion density.

5) Lower process temperatures.

6) Short process time.

7) Anisotropic etching.

8) Process repeatability.

SCI has designed the Quadrio 4 – RIE and Quadrio 5 – RIE systems (Figure 1) to operate effectively with physical plasma. These high UPH systems are equipped with a specially designed chamber that assures perfect RF and gas distribution throughout the whole chamber area. The carefully designed chamber geometry and surface finish assures the absence of unwanted sputtering or cross contamination and delivers an effective cleaning power.

Figure 1

Figure 1

As an example of Quadrio’s cleaning power, let’s consider the following application:

Second bond is referring to the bonding of a wire on the surface of a lead frame or substrate pad, in the wire bonding process. Previously, we have discussed about NSOP or Non Stick on Pad as a way to determine the bond yield of an assembly line. NSOL, or Non Stick on Lead, which in many aspects is similar to NSOP, refers to the bonding stich of the gold or copper wire on the lead frame during the wire bond process. It is also used to determine the bonding yield.

Figure 2 shows two heavily oxidized leads and below the same cleaned in physical plasma.

Figure 2

The following data was obtained during a qualification run performed by one of our customers, a leading semiconductor manufacturer, using one of our Quadrio RIE Plasma Cleaners:

Model: Quadrio 5 PE-RIE (figure 1), which has both Reactive Ion Etching and Plasma Etching capability.

Configuration: Reactive Ion Etching

Process set with 400 Watts of 13.56 MHz RF Plasma for 20 seconds

Process gas: Argon

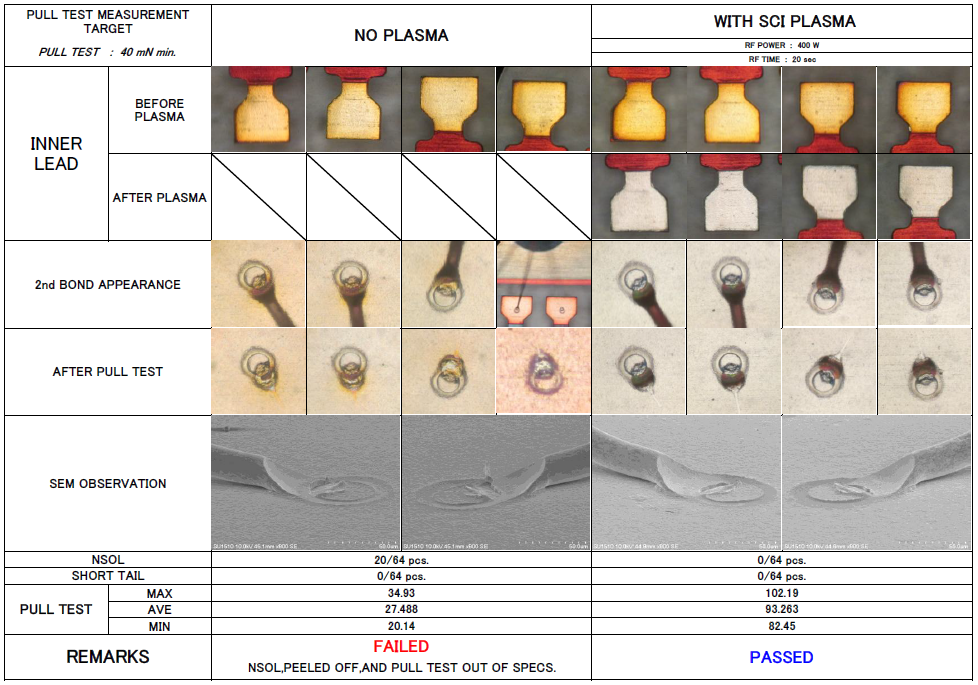

Figure 3 shows the compiled data obtained from our customer

Figure 3

Figure 3

The test shows a comparison between a treated and untreated leadframe. The total number of leads controlled in both cases is 64. The most obvious result is the difference in color of the leads. The oxidized ones, a dark yellow color, and the cleaned ones show a light grey.

The other images include general appearance of the second bond, the images after the pull test and the SEM images. The untreated parts show 20 failures over 64 while the treated parts show zero failures over 64. The untreated parts show failures described as NSOL, peeled off bonds and bond forces out of specification.

The pull test results are also very good (Avg. 27.488 for untreated parts, 93.263 for treated parts).

Metal oxides can form on the surface of a lead frame or substrate pad for many reasons including: bad storage in unprotected environments or, more effectively, heat treatment during the various stages of die assembly. In all cases, these oxides are a major culprit for reliability issues in semiconductor packaging assemblies. Highly efficient plasma cleaners from SCI Automation are a good choice for eliminating such oxides as well as eliminating traces of organic contamination obtained from the die attach curing process prior to wire bonding.

Pre-molding plasma treatment is also very effective with our systems. It allows to remove any residual organic contamination, it performs physical modification of the assembly surfaces and equalizes the overall surface energy to higher levels.

SCI Automation Plasma Cleaners combine the process strength, ion efficiency and throughput to qualify them as best in class equipment. With 15 years of experience, SCI Automation is your qualified partner for plasma cleaning applications. Feel free to share with us you application requirements.

| Download the SCI Automation Plasma Cleaning System Data Sheets to Learn More! |

|

----

Dr. Enrico Malatesta

CEO, SCI Automation Pte. Ltd. Singapore