In the past few months we have had the opportunity to work with potential customers who are looking to make the jump from manual die and wire bonding to automated solutions. There are a lot of considerations to take into mind when making this jump. This blog discusses some scenarios that may help others who are weighing this decision.

You may be wondering, what exactly does automatic mean? In some cases, customers have this pre-conceived idea of in-line handlers with carriers going from station to station with no operator intervention. No doubt about it, this is automation at its highest level. This can also be “overkill” in many situations. Palomar Technologies makes “automatic” die and wire bonders. However, a majority of our customers still use the manual load of parts. The main reason for this is because they run a high mix of products and are looking for flexibility in the fixturing and presentation of parts. One situation is that a customer may have a large, deep access RF Module that takes a good chunk of our bonders large work area, but on the next day they may be running hundreds of smaller parts. Flexible fixturing and heated work stages are a key component to the high mix approach.

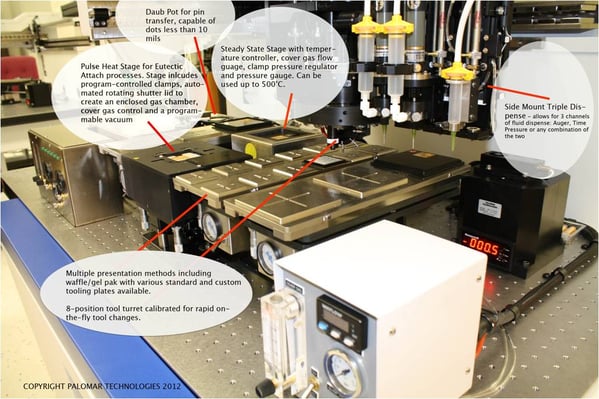

Palomar Technologies' die and wire bonders are designed to make it easy to exchange entire stages if required. We provide a variety of easy to adjust stages and tooling, as well as replaceable and interchangeable top plates. We also have a highly experienced and knowledgeable Program Management Engineering group, that design innovative and custom solutions for customer-specific challenges.

With a manual load solution, you will still reap all the benefits of an automated solution: your parts will be bonded quickly and repeatedly increasing the throughput, but more importantly, increasing the yield. This is true of both die bonding and wire bonding. You also free up the operator to do other tasks increasing productivity. The time between loading a new batch of parts is dependent on the part sizes, heat up time when required, and number of die placements or wire bonds per part.

With some of the largest wire bonding and die bonding work areas in the industry, Palomar Technologies takes advantage to present as many parts as feasible into the work areas at one time. If you are looking to make the jump to an automatic solution and wonder if it will make sense in your process application, give us a call.

Download these resources for more information:

| Guide to Automated Production Lines |

3800 Data Sheet | Value of Automation Interview |

|

|

|

----

Dale Perry

Regional Account Manager, Eastern Americas

Palomar Technologies, Inc.