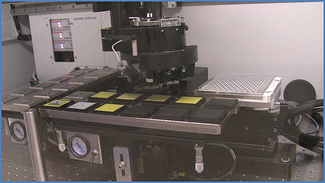

Here is a quick refresher on epoxy die attach and Anisotropic Conductive Paste (ACP). Using a flexible die bonder with 3 channels of fluid dispense and a daub pot, you will be able to perform a highly accurate and reliable bond.

How ACP Works

ACP works by trapping conductive particles between the corresponding conductive pads on the IC (integrated circuit) and the substrate. ACP consists of a very stable matrix of 3 micron to 5 micron polymer spheres. Each of these are nickel-gold plated and then coated with a final insulating layer that protects them against shorting through contact with a neighboring particle. The insulated particles are distributed in such a way that their incidental contacts in the X and Y axes are low.

Pre-Bonding

During the bonding process, the insulation in the Z-axis where the balls are trapped is pushed away. This allows the Ni-Au layer on the particle to conduct electricity between the IC and the substrate while not shorting in the X and Y directions. The epoxy then cures, locking the particles in this compressed state.

Maintaining Electrical Connection

The elasticity of the compressed trapped particles causes them to constantly press outward on both contact points. This helps to maintain electrical connections through a wide range of environmental conditions. Improvements in particle uniformity, dispersion, and particle coating technologies have allowed ACP now match or exceed the reliability of older solder technologies.

Post-Bonding

The final process subjects the ACP to high heat and temperature, permanently curing the epoxy and attaching the IC to the substrate. Although vast improvements have been made, an example of bonding profile would be 150-210'C and 40-300 grams/bump for 5-20 seconds.

To learn more, download these resources:

|

Epoxy Die Attach eBook |