SST recommends, designs, and fabricates tooling for die attach and lid seal with weights. Free floating individual weights are used for each device package. Some customers have questioned the cost of the weight assemblies and the need for such weights. Typical belt furnaces reflow solder operations are done without holding the components in place with weights. We will show X-Rays of die attach parts, with and without weights to highlight the benefits on using weights.

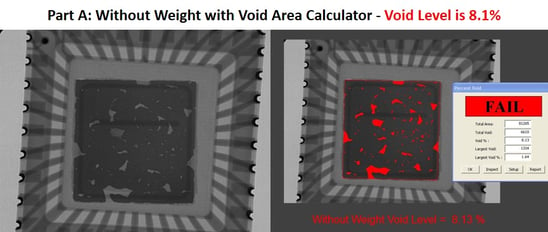

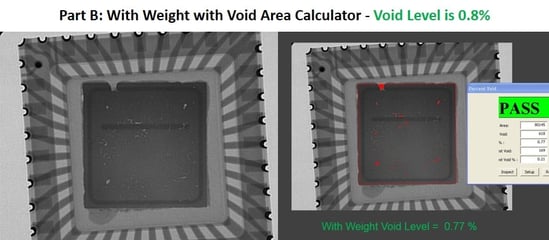

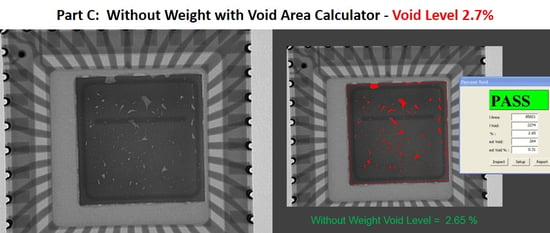

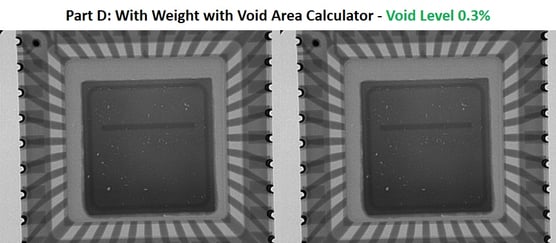

Samples will be prepared for side by side die attach comparison using 1mil AuSn solid preforms on a test die size of approximately 0.212 inch square. The X-Rays of the samples are included below.

It is quite apparent that the addition of the weight has an impact on the voiding level of the solder interface. With the application of weight, the void levels are less than 1%. Without weight, with the same reflow profile, the void levels are in the 3 to 8% range. SST has maintained that the weight ensures a complete contact of the solid solder preform to ensure complete melting of the solder and a uniform melting of the solder at the melting reflow temperature. This also ensures that the die is not tilted during the reflow operation and remains flat on the underlying substrate. Another advantage is that the weight holds the die in place and prevents inadvertent movement of the die during loading into the reflow oven

or during the reflow operation.

Download these resources for more information:

| Void-free/Flux-free Data Sheet | Model 5100 Data Sheet | Model 3150 Data Sheet |

---

Zap (Pierino) Zappella

Process Development Engineer

SST International