A production line consists of multiple distinct pieces of equipment linked together to provide distinct processes of your overall part build recipe. With an in-line assembly, packages are fed automatically through the production line via a system of process carriers and magazines in the same way as an island of automation. An island of automation consists of individual processes, such as component attach or wire bond, are performed within independent, automated work cells; the packages are fed automatically through the work cells via a system of process carriers (boats) and magazine handlers.

What is the Value of a Production Line?

The value of an in-line system is through higher volume, low-mix assembly of a single type of product with minimal or no product changeover and greater yield due to reduced operator contact with the product and materials. Since in-line assembly process operations run together as a whole production line, this configuration may require less labor to operate than islands of automation.

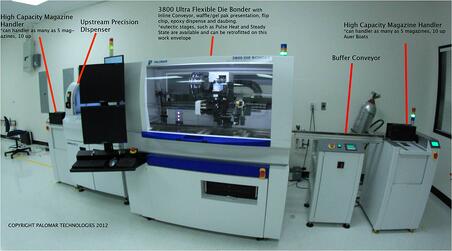

A fixed production rate allows for more accurate production planning and potentially higher throughput. Larger assembly lines can take on such aspects as UV epoxy curing, ultra-high accuracy pick and place, heated tools for eutectic die attach, curing ovens, hot bars, precision dispensing systems, wafer die ejectors (punch ups), and customized presentation stages for odd-shaped devices.

Service and Line Support

Palomar Technologies has been in the automated line business for decades, and have been constantly challenged to help our customers streamline a high-throughput production without compromising product integrity. There are 5 Core Competencies for Automated Microelectronic Assembly Lines:

- Experience and expertise

- Flexible, leading-edge process equipment

- External partners and alliances

- Process development

- Superior service

One of the complications of having a production line is sustaining and supporting many pieces of equipment from multiple vendors. If one piece of equipment in a production line is inoperable, it impacts the entire line. Beyond the purchase of equipment, it is invaluable to have service and support for the lifetime of those machines. Offering service installation and support of production lines is a must. Service actions of Palomar purchases include:

- Line installation

- Training for all production line equipment

- Service of all line equipment, including preventative maintenance and repair

- If line operators change over time, Palomar can provide follow-on training

- If required, Palomar can assist in relocating a production line at a later time

When considering equipment purchase, whether it be an island of automation or an entire production line, it is essential to consider the service offered with that purchase. The support provided after the purchase is just as important as prior to and during the purchase.

Download these resources for more information on automated lines and service support:

| Guide to Automated Production Lines eBook  |

Process Development Consulting Data Sheet  |

| Bonder Boot Camp Training Data Sheet  |

Field Services Data Sheet  |

----

Tim Hughes

Director of Global Customer Service

Palomar Technologies, Inc.