Although there is continued effort in the semiconductor packaging industry to reduce package size along with the never-ending pursuit of cost savings, there remain a significant number of applications requiring a wildly different set of capabilities for die and wire bonding.

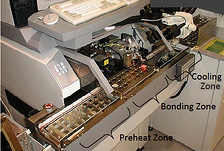

The RF, microwave, high brightness LED (HB LED) and optoelectronic markets are characterized by lower volume and higher mix when compared to semiconductor packaging. This requires different levels of manual and automatic assembly process steps depending on product and manufacturing maturity. Suppliers can help customers through the various stages of manufacturing automation by providing manual, semi-automatic and fully automatic islands and lines of equipment and process.

characterized by lower volume and higher mix when compared to semiconductor packaging. This requires different levels of manual and automatic assembly process steps depending on product and manufacturing maturity. Suppliers can help customers through the various stages of manufacturing automation by providing manual, semi-automatic and fully automatic islands and lines of equipment and process.

"RF, Microwave, and Optoelectronic Packaging Die and Wire Bonding Case Studies" is a highly technical paper, which dives into the primary differences between semiconductor and RMO packages as well as associated equipment sets and material handling options. The paper covers three cases, providing an overview of the requirements and tools available to handle RMO products:

is a highly technical paper, which dives into the primary differences between semiconductor and RMO packages as well as associated equipment sets and material handling options. The paper covers three cases, providing an overview of the requirements and tools available to handle RMO products:

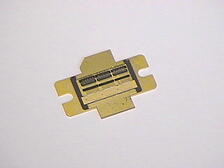

- Case 1: RFSOE Product (High-Accuracy Die Bond + Semi/Automatic Wire Bond)

- Case 2: Optoelectronic Printer Product (Ultra-Accuracy Die Bond)

- Case 3: High Brightness LED Matrix Product (High-Accuracy Die + Semi/Auto Chain Wire)

Download the paper to learn more!

---

Jessica Sylvester

Marketing Communications

Palomar Technologies