Today’s multipurpose wire bonding machines are required to deliver a combination of wires, bumps and specialty interconnects. Multipurpose wire bonders accommodate large work area, deep access, and a complex mix of bond surfaces, wire shapes, and bumps—many odd-form packages rely on the capabilities of a multipurpose wire bonder because these complex bonds simply cannot be bonded on semiconductor bonders.

Palomar Technologies Sr. Scientist, Daniel Evans, and Sr. Applications Engineer, David Rasmussen, recently presented their latest technical paper “Multipurpose Wire Bonding – Wires, Bumps and Combination Interconnects” at the IMAPS Wire Bond Topical Workshop held on July 14th in concurrence with SEMICON West 2011. Complex, deep access and odd-form wire bonding were very topical on the SEMICON show floor and in the Palomar Technologies booth this year as attendees are searching for hi-rel and fully automated wire bonding systems.

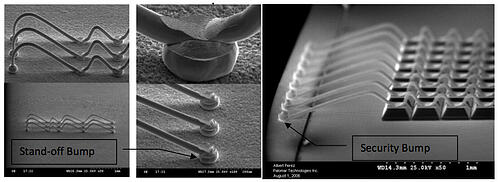

This highly technical paper covers four cases highlighting the range of applications that can be bonded on a multipurpose bonder:

Case 1: Ball bump examples

Case 2: Deep access of 0.535” using a 0.750” capillary

Case 3: Ambient wire bonding to a 6” tall package

Case 4: Batch load tray (mechanical and vacuum clamping)

Download the technical paper to learn more about hi-rel, fully automated wire bonding systems.

----

Jessica Sylvester

Marketing Communications

Palomar Technologies