Many manufacturing-based businesses are linked to a market of secondary (used), lower-cost equipment. Secondary die attach equipment, such as the 3500-R Die Bonder, fits in the product positioning curve where low cost meets high-accuracy/large work area.

Buying a secondary/used die bonder does not always lend itself to obvious check boxes. In this blog, we’re going to specifically talk about high-accuracy, automated die attach equipment—where the value rests and what to keep in mind when shopping for a second-hand die bonder.

The value of a Palomar Technologies 3500-R Die Bonder is in its long standing reputation as a solid, reliable, large work area, high-accuracy die bonder. The installed base of these machines spans more than 20 years and in hundreds of factories around the world.  These machines are automated component placement work horses. Recently, a 17-year-old 3500 series system came through the Palomar Technologies factory for the factory-certified refurbished program and resulted in meeting repeatable 4µm accuracy on a test coupon! Incidences like this can only result from properly regulated and factory-backed equipment refurbishment, proving that correctly refrubished bonders can still perform consistently at a very high level.

These machines are automated component placement work horses. Recently, a 17-year-old 3500 series system came through the Palomar Technologies factory for the factory-certified refurbished program and resulted in meeting repeatable 4µm accuracy on a test coupon! Incidences like this can only result from properly regulated and factory-backed equipment refurbishment, proving that correctly refrubished bonders can still perform consistently at a very high level.

Secondary Equipment Market Share

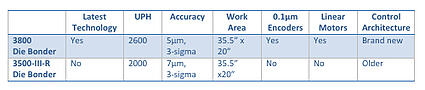

In 2010, used manufacturing equipment was reported to be a $6 billion market. That market value continues to rise and has increased another 77% today—13% of which includes all secondary semiconductor equipment. Here at Palomar, we have a seen not only a strong demand for new 3800 Die Bonders, but also for its certified, factory-refurbished predecessor, the 3500-R Die Bonder. Which machine an organization purchases really depends on the application, production needs and budget. Here are a few of the main draws to these automated, large-work area systems:

If you are part of the 13% of the secondary semiconductor equipment seekers, and you are looking at purchasing a high-accuracy die bonder, you are going to be posed with three options:

Buying directly from the factory and getting the “factory-certified” OEM stamp of approval with specifications/performance tests, software license and multiple service support options

Buying directly from the factory and getting the “factory-certified” OEM stamp of approval with specifications/performance tests, software license and multiple service support options- Buying from a private seller where there is no guarantee—the bonder is “as is”; options for factory support are up the discretion of the OEM (not guaranteed)

- Buying from a 3rd party broker—the equipment often goes to the highest bidder, and while this is becoming a more legitimate business, you are still buying “as is” with no guarantee and, again, factory support is at the discretion of the OEM

Used? Refurbished? What's the Difference?

No matter how or where you choose to buy your equipment, the purchase warrants careful consideration before making this important investment.

First, there is a major difference between “used” and “factory refurbished”:

- Used = you are buying from a 3rd party, or “as is” – there are no guarantees to the current condition of the system

- Factory-refurbished = you are buying from the factory (OEM) and getting a guarantee of support and performance

Secondly, die attach equipment is highly complex. Used 3rd-party die attach equipment carries very large risk, financially and operationally. While not impossible, getting the machine to do what you purchased it to do comes at a cost; the money and resources you are going to spend will probably cost more than purchasing a factory-certified machine. Any savings realized up front will be lost in getting the machine working at the desired performance. Buying 3rd-party equipment is financially risky.

Thirdly, these are niche products with a very limited number of people in the world that know how to properly condition, set up, and run the machine. A 3rd-party purchase is highly disconnected from the OEM and, therefore ultimately, the original engineering experts and support team.

Additional Risks Associated with 3rd-Party Purchases

This year at SEMICON West, the risks associated with purchasing and supporting secondary or used equipment were discussed: “[…]the lack of engineering talent to work with the complex equipment[…]; many of the qualified field engineers that knew this equipment have retired or gotten out of the semiconductor industry”.

Software licenses on 3rd-party 3500 Die Bonder series equipment do not transfer with ownership. Purchasing these licenses are part of the cost going the 3rd-party route to legally operate the machine. A software license can be purchased, but the machine has to be inspected and upgraded, which comes at an added cost.

Used 3rd-party 3500 Die Bonder series machines are often not serviced properly (or even at all!) to accept a Bonder Performance Upgrade (BPU); it could be that certain components may be obsolete, or that some non-replaceable aspect has become defective over time. In this case, even if the OEM wanted to support it, they could not. You could buy a new machine for what it would cost you to tear the old down and build it from scratch.

It has been seen across the secondary equipment market that “there is now no source for original part, or even “'re-manufactured' parts…the only option to keep this equipment going is to use expensive custom part production – an option which is unattractive to the current equipment owner, even if it was the sole possibility…" (SEMICON West 2012, Daily Digest).

A factory-refurbished die bonder machine comes with the following guarantees:

Low-cost alternative to the new, leading available technology

Low-cost alternative to the new, leading available technology- The machine attains the programs and expected performance you’ve purchased it to do

- A mutually agreed upon acceptance test procedure before the machine is packed up and shipped to your facility

- Warranty

- Bonder software license (and additional software, if required)

- Factory support program eligibility

- Extended warranty or service contract offerings

- Bonder maintenance, operations and programming training offerings

- Program options, such as eutectic stages, epoxy dispense systems, custom tooling and fixturing, wafer die ejectors, and even automated material handling systems

- Spare part availability and access

- Access to the system's engineering experts

The spare part aspect is an element of financial consideration when deciding between a 3rd-party purchase or from the OEM. In fact, this may be the most important aspect—assuming the bonder is processing your application correctly. Part obsolescence is a major problem in the used equipment market. Purchasing directly from the factory not only gives you a working machine, but the option to be on the priority list for spare parts regardless of the age of the equipment. This priority list comes in the form of a service contract or extended warranty, and is only offered to factory-direct customers.

When making a capital equipment investment, taking into account these facts will help you make the right decision for your organization.

Interested in a 3500-III-R? Click here to submit a request.

Want to sell your 3500-I, -II or -III Die Bonder? Palomar offers a Bonder BuyBack program, offering substantial credit towards the ownership and support services of the new 3800 Die Bonder.

----

Richard Hueners

Director of Sales and Marketing

Palomar Technologies, Inc.