About

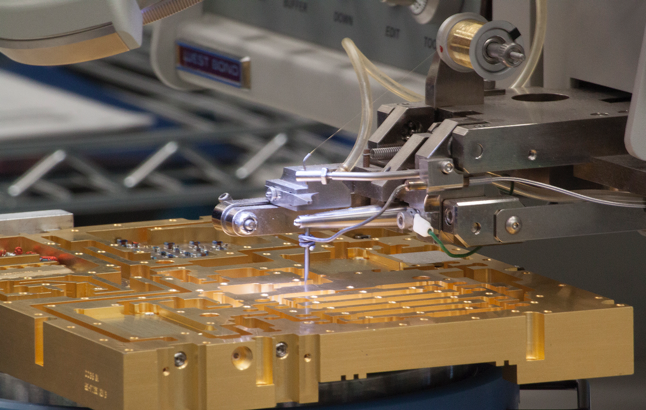

Palomar® Technologies is a leading supplier of automated microelectronic assembly machines and contract assembly services with specialization in precision die attach, wire bonding and vacuum reflow solutions. We are proudly an independent USA-based company, owned and operated by local management.

Products

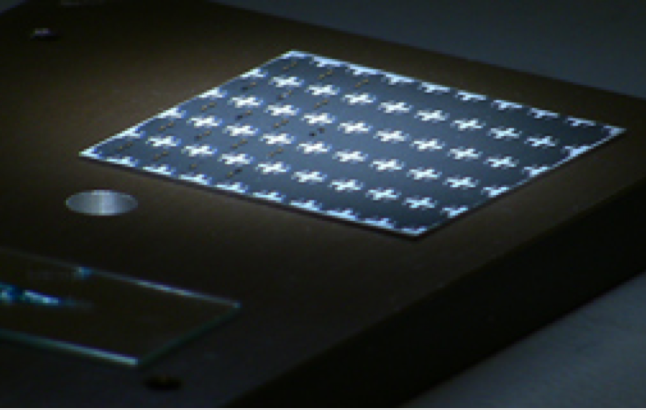

SST Vacuum Reflow Systems

Wire Bond Features

Applications

Palomar® Technologies provides packaging solutions for a wide variety of industries and applications. With 45+ years supporting the semiconductor and photonics industries, Palomar now supports a wide range of industries including automotive, lasers, LEDs, medical & bio photonics, military/high reliability/MEMS, power semiconductors, RF/microwave/wireless, sensors and telecom/5G/Datacom. Select your industry to learn about Palomar’s solutions.

Die Bonding

Innovation Centers

Palomar® Technologies offers multiple locations with full-service OSAT laboratories which provide volume manufacturing, process development, package prototyping, assembly, test, and measurement for processes such as die attach, wire bonding, vacuum reflow, and more.

Resources

Get access to our entire knowledge database: read blog articles and download materials.

Contact Us

Contact us for more info about our Total Process Solution including die bonders, wire and wedge bonders, SST vacuum reflow systems, and Innovation Centers.